Our engineers will advise the customer on how to reduce the number of welded joints

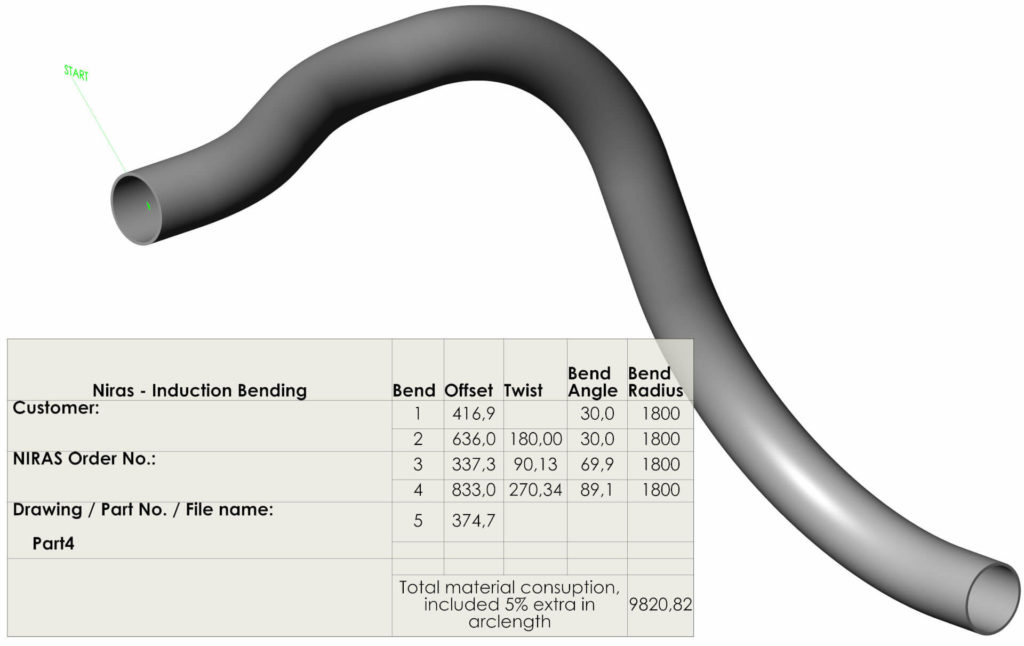

When NIRAS receives a drawing, our engineers will advise the customer on how to reduce the number of welded joints. Close cooperation at the planning stage can enable great savings in the production of a pipeline.

Induction bending allows to increase the radius of the bend quite seamlessly, bringing advantages such as better flow and reduced internal wear.

Reduced operational costs can result from the reduction in pump force and lower maintenance costs because the bends will not need to be replaced as often.

From a design point of view, you do not need to be tied to one specific radius; we can steplessly adjust the radius from 1,5D (1,5 times the nominal outside diameter of the pipe) all the way up to 22,000 mm.

You do not have to plan your pipeline with 45° or 90° bending angles; using induction bending we can seamlessly produce any desired angle from 1° to 270°. Please take a look at our Design Criteria for induction bending, found under the downloads menu.